Floor chipping machines are efficient for removing coatings and other materials from concrete slabs. Importing the machine from China can provide cost-effective solutions, but it’s crucial to understand your equipment needs thoroughly. In this guide, we’ll focus on how to choose the perfect floor chipping machine from China manufacturers.

Understanding Your Equipment Needs

Most machines produced in China have difference from those in USA and Europe, as they are designed to meet the China market needs, especially in the electrical aspect. Before you import a floor chipping machine from China, it’s essential to assess your machine needs and requirements.

1. Type of Work

What type of work will you use the floor chipping machine for? What are the concrete structures? Is it primarily for concrete surface preparation, coating removal, or more extensive concrete removal tasks? If you need light or heavy duty machine? Understanding the primary tasks will help you narrow down your options.

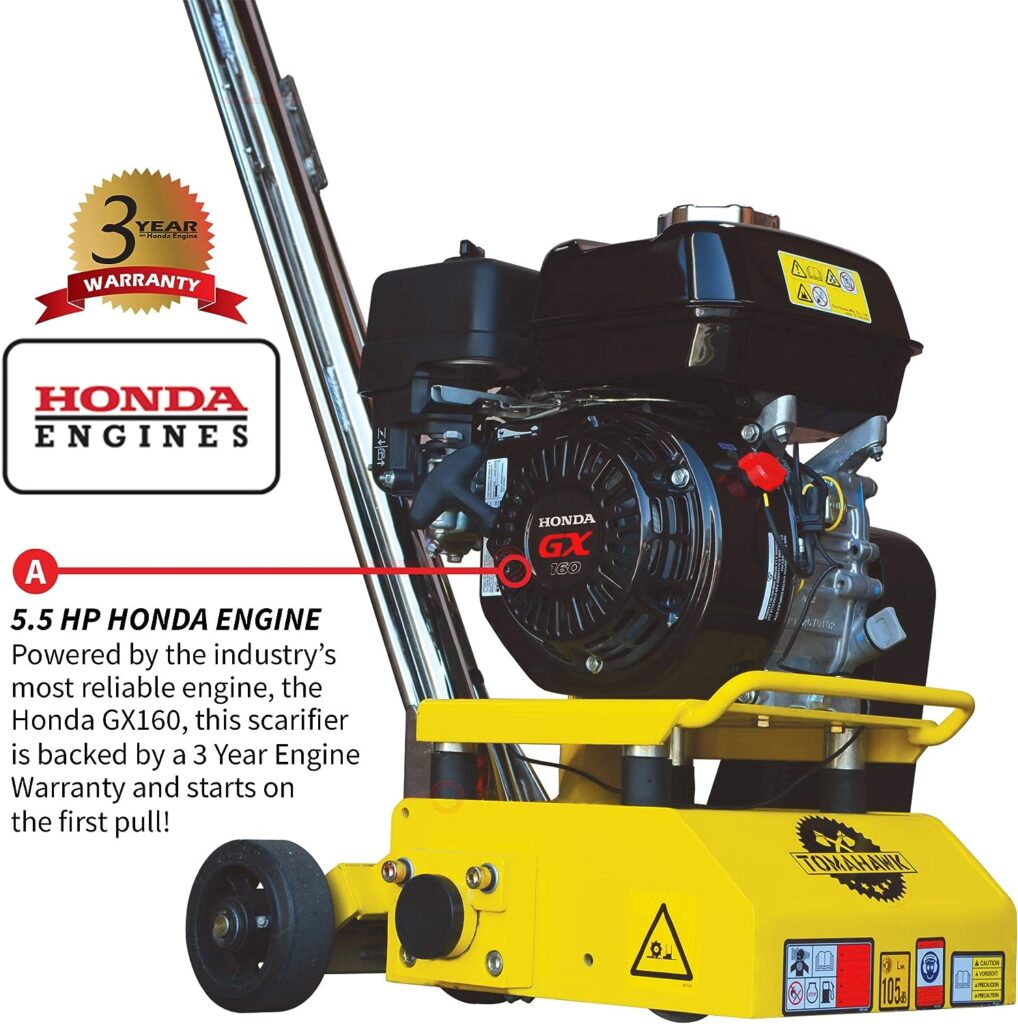

2. Power Source

Floor chipping machines in China come with different power sources, including diesel, gasoline and various electric motors. Gasoline of the machine blows minimum 3600 rpm per minute. Motor of the machine runs usually 2800rpm per minute. Determine whether you’ll primarily use the machine indoors or outdoors. Your choice should align with your project requirements and the availability of power sources at your job sites.

3. Electric Considerations

If you opt for an electric machine, pay attention to local electric requirements. For indoor floors, motor is the most common choice. China differs greatly in the electric aspects. Ensure that the machine matches the local voltage, Hz, current, government mandatory, and so on.

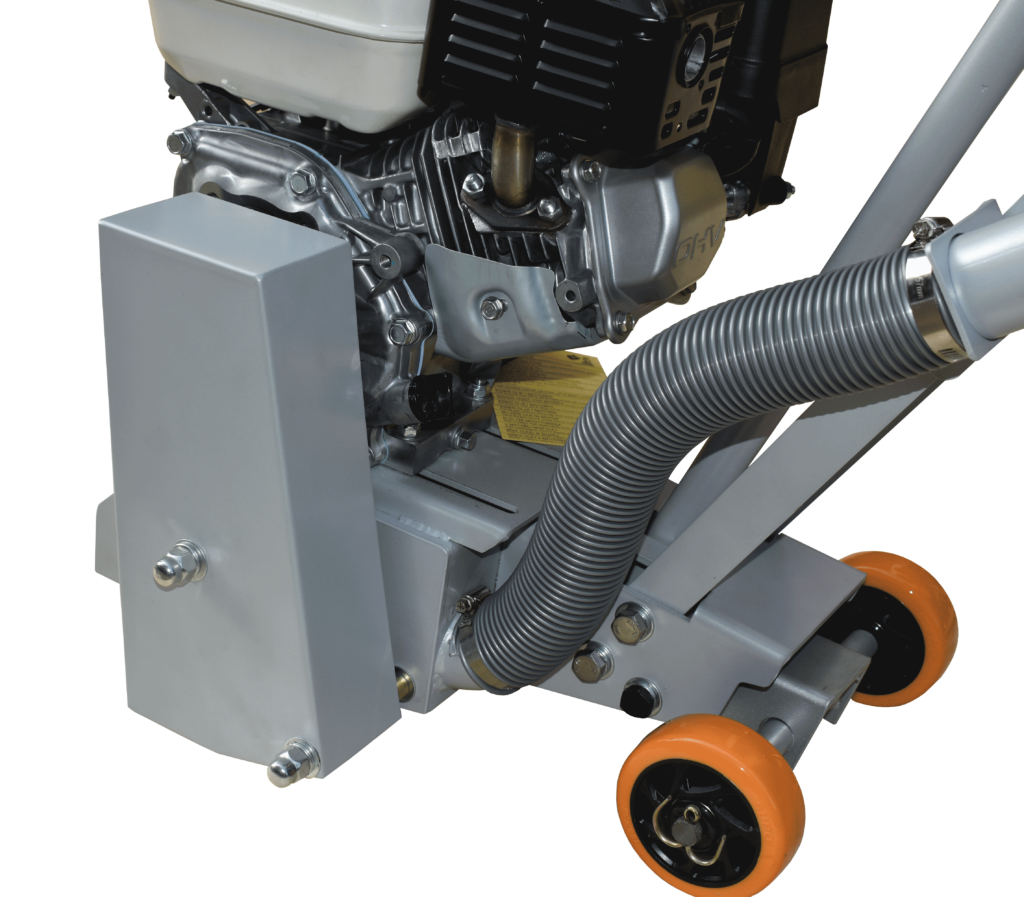

4. Spare Parts and Tooling

The machine could use various and efficient spare parts: steel cutter, TCT (Tungsten Carbide Tipped) cutters, diamond blades, etc. Consider the floor finish which you hope to get,related with concrete structures, as well as their cost, when making your selection.

5. Other factors to consider

Noise of the machine; the noise of motor type will be much smaller than the diesel and engine type. For example, the noise of gasoline engine is 104DB.

Vibration of the machine; we have to accept an factor that vibration of floor chipping machine is much bigger than some concrete slabs machines like grinding machine and shot blasting machine. But excessive vibration is a design or mechanical problem.

If it is comfortable to operate? Typically a well designed floor chipping machine feels less fatigue and vibration when operate.

Research on the China supplier

It is important to research into China suppliers of the machine. After all, the mechanical equipment depends on the credibility and expertise of the factory. Here are some tips:

1. Professionalism and Manufacturing Experience

Evaluate the manufacturer’s professionalism and experience. Ask questions such as:

How many years have they produced these machines in China?

Visit their website is an efficient way. A well-organized and informative website often reflects their professionalism for the equipment.

2. Balancing Budget and Quality

Price is a significant factor in your decision-making process. China manufacturers are known for their competitive pricing, but beware of excessive low prices. Actually China labor costs increase too. Greater reliability, craftsmanship, and aesthetics of an efficient machine all contribute to its elevated cost.

3. Spare Parts Availability

A dependable supply of spare parts for a machine is critical for the long-term maintenance and performance.

How many days usually they need to provide the accessories of the machine from China to your location?

Having a clear mind on spare parts’ availability prevents unexpected downtime in the future.

4. Post-Sales Service and Guarantee

Another crucial aspect to investigate is the supplier’s post-sales service and guarantee. You could use the below questions as a start.

What is the supplier’s guarantee policy for the machine?

How to replace the spare parts? If they provide video support?

In case the machine encounters issues, how do they address and resolve the problem?

Understanding the support you can expect from the machine supplier is essential for a hassle-free experience.

Placing Your Order

Once you’ve thoroughly evaluated the China manufacturer and are ready to move forward with the machine purchase, paying attention to the details is paramount. Here are key considerations when you are ready for purchase:

1. Order Details

Ensure that the China manufacturer fully comprehends your specifications for the machine. Or request the China supplier include your equipment requirements in the proforma invoice.

2. Price Terms and Total Cost

International business involves various price terms, such as EXW, FOB, CIF, CNF, DDU, and more. Each term carries different implications for where the cargo is sent and the associated charges. Calculate the total cost from China to your warehouse, including taxes, to get a comprehensive understanding of the financial aspects.

3. Bank Information and Company Stamp

Pay attention to the beneficiary name on the transaction. Ensure that it matches the company name. China companies typically have a company stamp, so inquire them stamp the invoice for added authenticity.

4. Shipping Arrangements

Clarify if the China supplier could handle the international shipping. Clear communication on shipping logistics is crucial for both the seller and the buyer.

5. Consider a Sample Order

Consider placing sample equipment for testing purposes. This allows you to assess the quality of the China equipment firsthand and ensure it meets your requirements.

In conclusion

In conclusion, selecting the right floor chipping machine from China involves careful consideration of your specific needs, thorough research, and collaboration with reputable suppliers. By following the comprehensive guide provided, you’ll be well-equipped to make an informed decision and acquire a high-quality and efficient machine that meets your flooring removal requirements. Happy chipping!